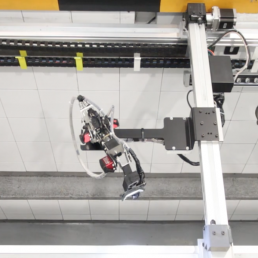

ITV ROBOT

Vehicle technical inspection robot

Robot to improve the quality of people's work

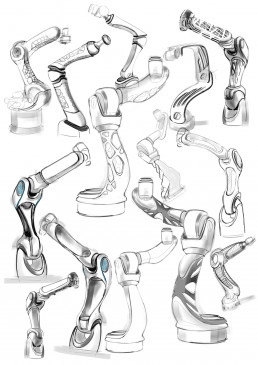

Development of a proof of concept to use robotic arms for the lower technical inspection of vehicles in pits.

Technology

The part of the work of inspecting vehicles underneath them is something that we do not want for our workers, that is why we have developed a robot concept adhoc to the existing workspace of the technical vehicle inspection facilities, allowing them to obtain as much, or more information without putting yourself at risk.

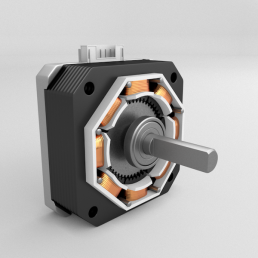

6 DOF PCB Board Controller

We have developed a control board to manage the movements of all the motors that make up the robot arm, as well as all the accessories: cameras, ir sensors, proximity sensors, relays, lights ...From our experience developing hardware for 3D printing, we have used numerous advancements in managing motor bouncing, jerky movements, and light dimming to achieve fluid motion and perfect vision.

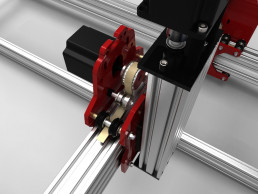

2 joystick & 6 DOF in 360 degrees

Multiple stepper motors of very high resolution with systems of linear guides and very precise bearings provide together with the software and firmware that reduces vibrations and makes the linear and fluid movements, a perfect focus and vision.

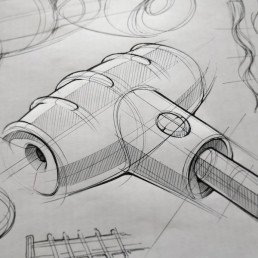

Better than eyes

We use cameras to record inspections with various UHD camera systems, IR camera and night vision, to be able to perceive details that escape the human eye, even to be able to highlight through IR lights, fluids and other components that may come off the parts of vehicle.

Movement learning

By training the movements of the robot, it can learn them, and be able to sweep or position itself at certain control points that we pre-set with the push of a button.

PROTOTYPE WORKING

Inspection and operation of the robot

The good performance of the robot has been validated with the professional inspectors of the stations, as well as requests for future improvements.