What is an SMT line and how does It work?

Surface Mount Technology (SMT) is at the forefront of modern electronics manufacturing. In this post, we explain in detail what an SMT line is and how it enables both rapid prototyping and series production of electronic circuits and PCBs at blackdevice.

The role of an SMT line in electronics production

At blackdevice, our SMT line is pivotal for both the development and testing phases of our products and projects. It allows our electronic engineers to transform a hardware design into a fully assembled circuit board in a fraction of the time compared to traditional methods.

What’s an SMT line?

An SMT line (Surface Mount Technology line) is an automated assembly process used in electronics manufacturing. It involves placing electronic components directly onto the surface of a printed circuit board (PCB), rather than inserting them through holes. This method allows for faster, more compact, and efficient production of electronic devices. SMT lines are widely used in the industry due to their ability to support high-density component placement and automated assembly processes.

From design to production: The process explained

-

Hardware design and component sourcing.

Our process begins with the electronic engineers designing the hardware. From these designs, we generate a bill of materials (BOM) which lists all required components. We then place orders with our trusted suppliers to source these components.

-

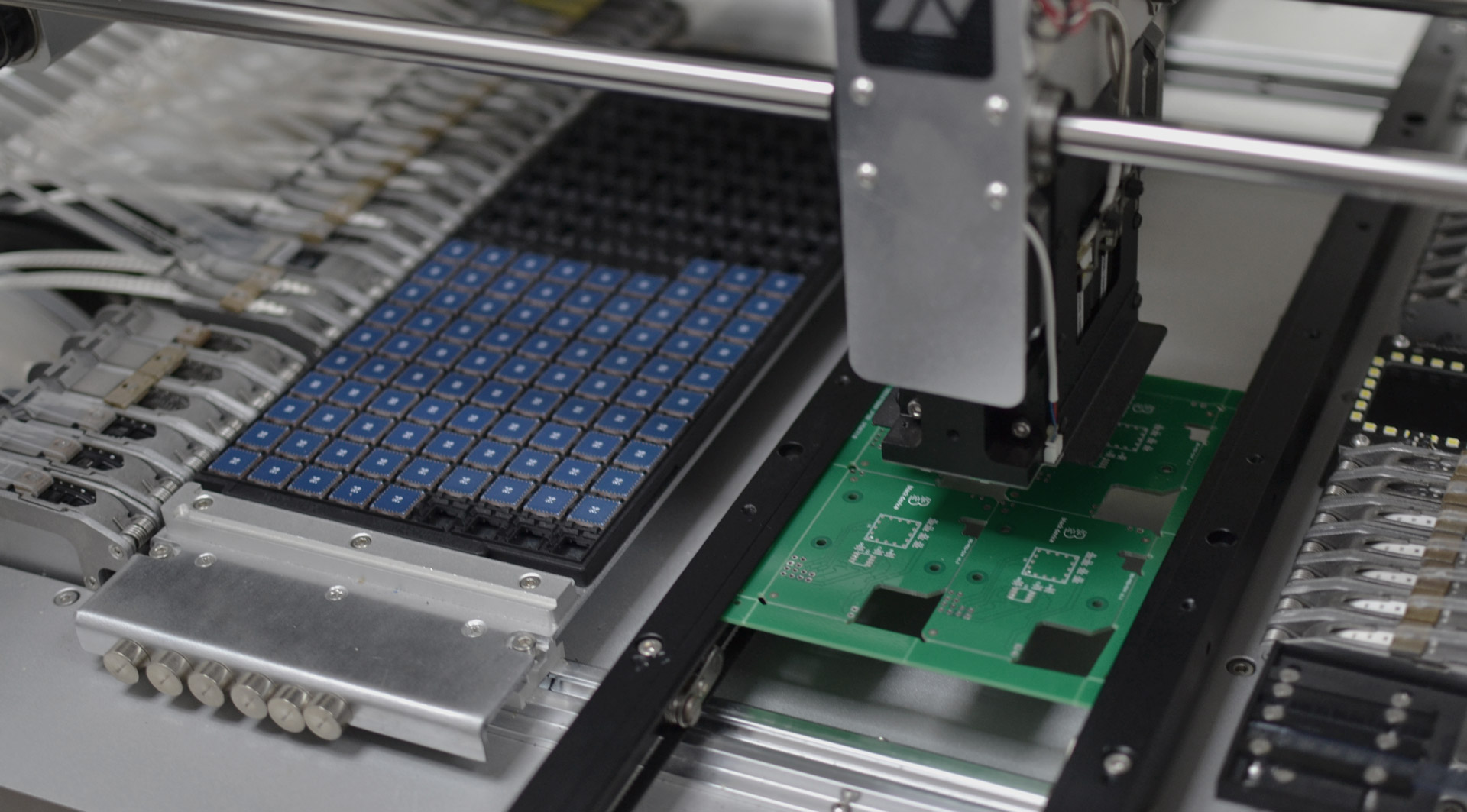

Loading the SMT Machine.

Once the components arrive, they are loaded onto the SMT machine. This is done via feeders—small, specialized holders that act as guides. The machine’s pick and place system uses these feeders to identify and position each component precisely on the PCB based on a coordinate file generated during the PCB design stage.

-

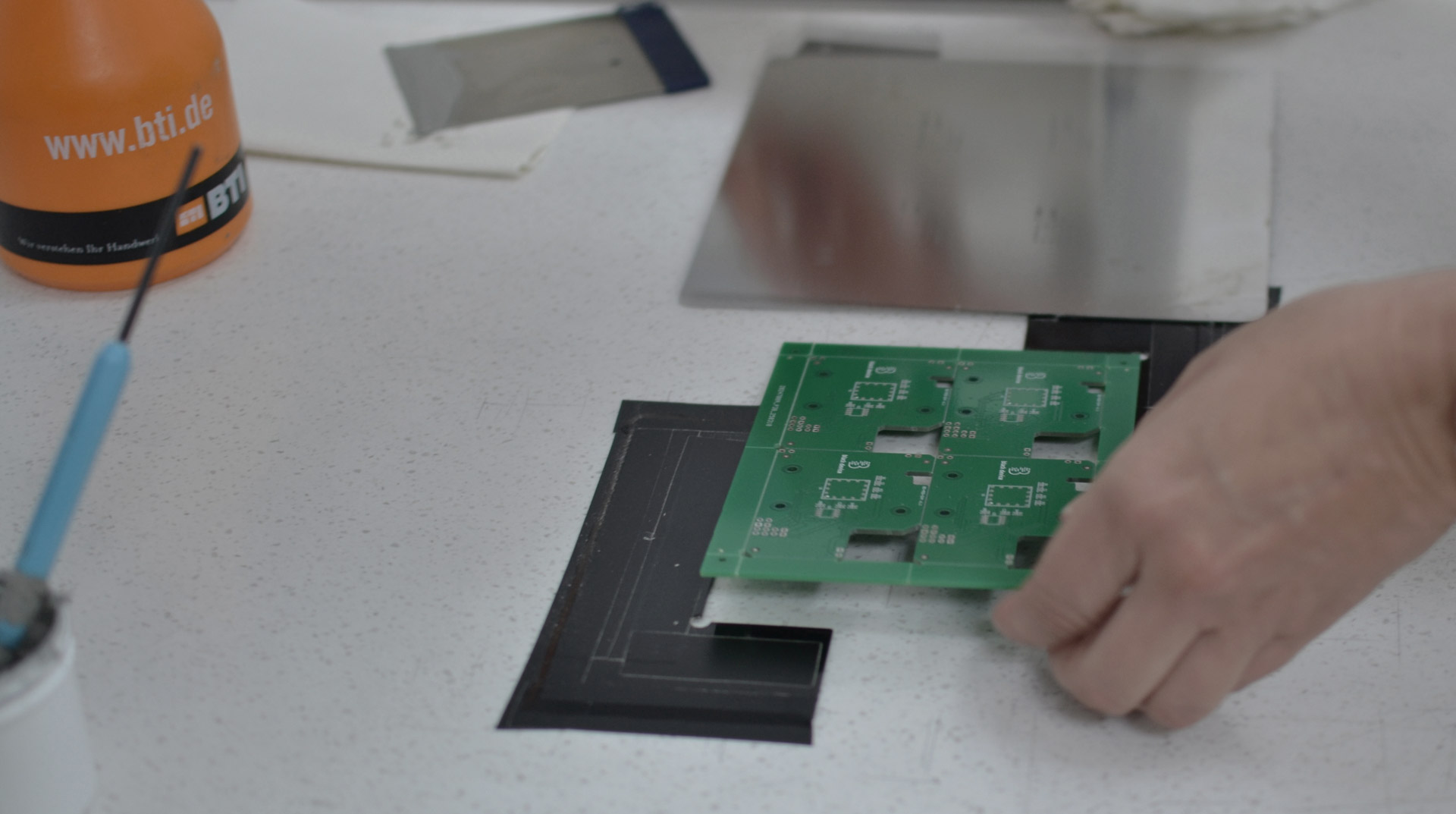

Solder paste application.

Before components are placed on the board, solder paste is applied using a stencil. The stencil is a custom template that contains openings for each component’s footprint, ensuring that the paste is accurately deposited for optimal soldering.

-

Automated component placement.

With the solder paste applied, the PCB is fed into the SMT machine. The board is automatically moved along a system of rails until a camera-equipped vision system detects fiducials—small alignment marks on the PCB. These fiducials help confirm that the board is correctly positioned, allowing the pick and place machine to accurately deposit each component in its designated location.

-

Soldering via reflow oven.

After all components are placed, the PCB is carefully examined to ensure precise placement. The board then passes through a reflow oven, where controlled heat melts the solder paste. This process creates strong, permanent connections that firmly attach the components to the PCB.

Prototyping and limited series production. A vital part of our process.

Our compact SMT line is not only essential for rapid prototyping but also for offering small-scale manufacturing services. This flexibility allows us to adapt to any production scale, ensuring we can fulfill the prototype and production needs of both small clients and large enterprises. By streamlining our development process, the SMT line is a key factor in delivering enhanced services and faster turnaround times to our customers.

Conclusion

In summary, the SMT line at blackdevice is a cornerstone of our production strategy. It significantly speeds up our development process and allows us to offer both rapid prototyping and flexible production volumes. Whether you’re a small startup or a large corporation, our SMT line helps us meet your unique needs, ensuring every PCB is built with precision and care.

Check out the video version of this article and subscribe to our YouTube channel and see our SMT line in action!